CONVERG3D

Beam me up!

The heart of our process starts with the Einscan HX scanner. Geometric data is captured with the handheld scanner and recorded on a laptop PC. Accurate to within 50 microns, the HX is is sensitive enough to detect a scratch in an otherwise flawless coat of paint. Scanning modes include laser, structured light, and hybrid, with the ability to scan in full color.

#1 - The Equipment

For our example, we started with an antique bushing, long since out of production. It was quickly established that the only realistic path forward was to reverse engineer replacement bushings using the original as a scan subject.

#2 - The “Problem”

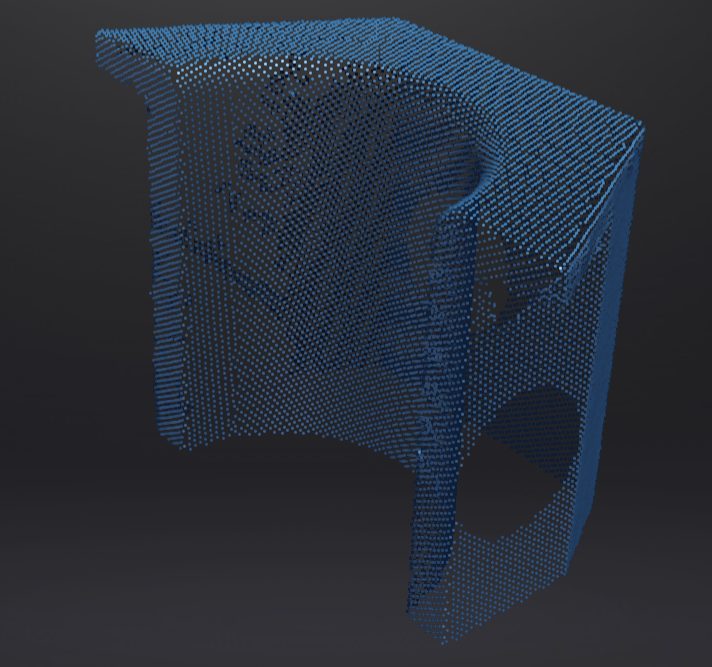

The data collected by the scanner form a “point cloud”. This is a digital representation of the physical part with each “point” being a specific location on the part detected by the scanner. From here, the digital file can be “meshed” to join the points into a digital shell. The mesh will provide closed geometry that we can then process in engineering software, or simply 3D print.

#3 - The “Point”

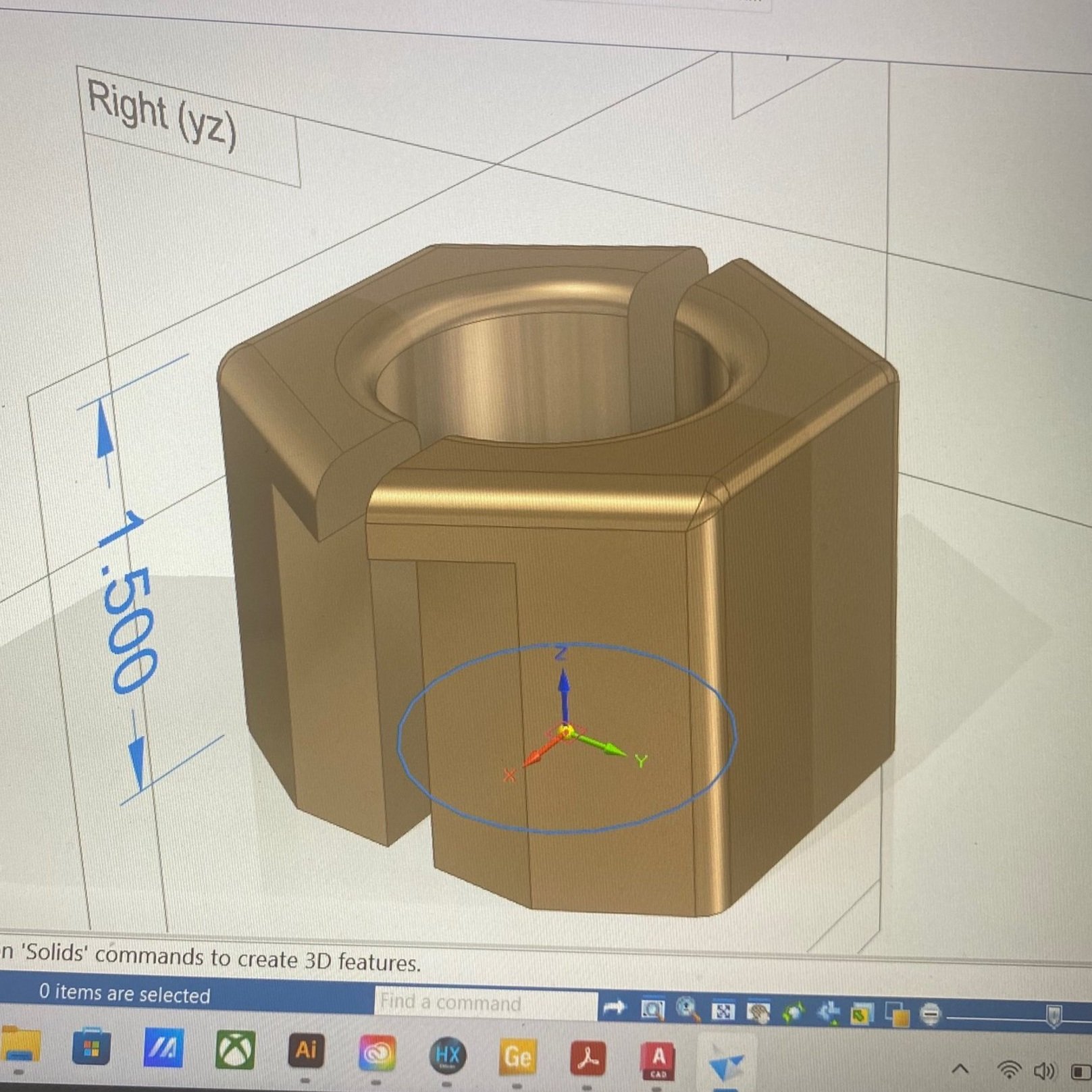

For our example, we needed to reverse engineer to specified tolerances with consideration given to machining that was to be done for proper fit and function. This was done using a suite of engineering software. For our bushing, the scan was modified and 3D printed to create a mold which was then given to a foundry to be cast in bronze, and then milled for proper fit. We are happy to provide guidance to help you understand the best options for your specific project!

#4 - The Details

Bytes become a bushing

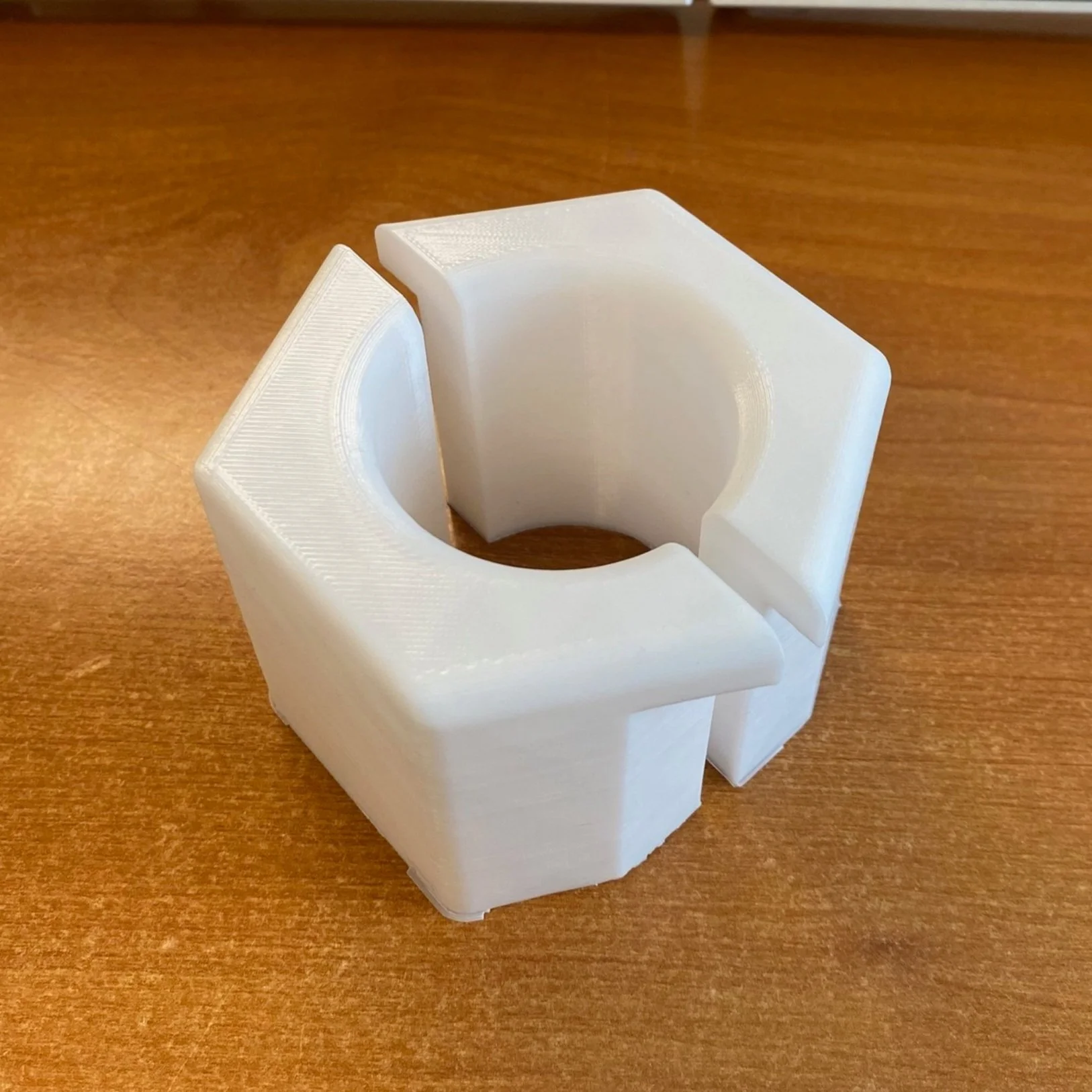

3D printed prototype used for test fit.

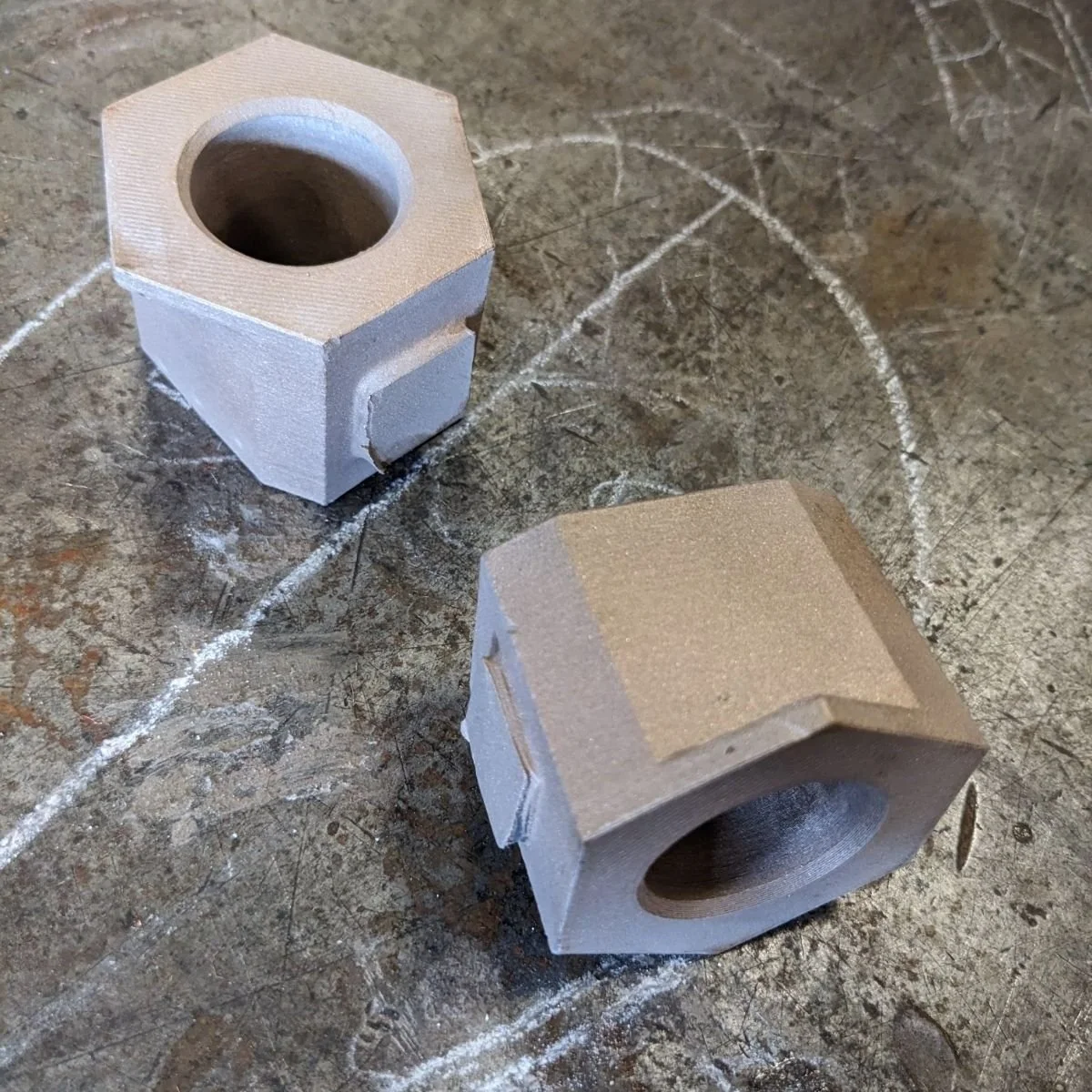

Sand cast of bushing using 3D print to act as a mold. This process is virtually the same manner as has been done for thousands of years.

Finished bronze casting ready for machining.

Note: Converg3D will work with trusted local artisans and fabricators to best suit your project needs and requirements.